- Why are companies importing special-shaped component plug-in machines

- Brand advantages of Tungson multifunctional fully automatic special-shaped component plug-in machine

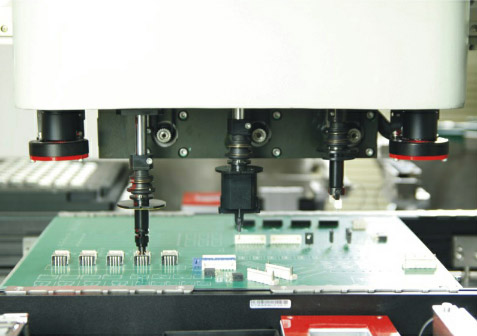

- The second generation "OCM-II Multi functional Alien Component Plug in Machine" has been successfully launched. Start simultaneously

- Who can perceive the opportunities and make the right choices in the crisis of the transformation of the manufacturing industry?

- Experiential training enhances the company's competitiveness

- Tungson Automation held a fire drill

Address: 5th Floor, Building B1, Songhu Zhigu Research Center, No. 6 Minfu Road, Liaobu Town, Dongguan City, Guangdong Province

Tel:0769-85389385

Fax:0769-85411416

E-mail:sales@tungson.hk

During the installation process of the plug-in machine, there may be welding phenomena, and the materials and parts required here are quite specific; There will be different requirements for different components, which is also a guarantee for the quality of subsequent products.

Welding materials have a significant quality impact on the safety of welded structures, and their composition, physical properties, and process performance should comply with the corresponding national standards. Construction enterprises should adopt sampling methods for verification.

1. Welding materials should be stored in a dry and well ventilated place, with dedicated personnel responsible for safekeeping, drying, distribution, and recycling, and detailed records should be kept.

The storage requirements for welding materials are mainly to prevent corrosion, moisture, deterioration, and even detachment, which may affect normal use.

The drying of low hydrogen welding rods should meet the following requirements:

1. Dry the welding rod at a temperature of 300-430 ° C before use 0~2h, or dry according to the welding rod instruction manual provided by the manufacturer. The temperature of the oven when placing the welding rod should not exceed half of the final drying temperature, and the drying time should be calculated from the moment the oven reaches the final drying temperature;

2. Dry low hydrogen welding rods should be stored in an insulated box with a temperature not lower than 120 ° C for later use; When in use, it should be placed in an insulated cylinder and taken as needed;

3. The drying time of welding rods should not exceed 4 hours. For welding rods used for Class III and IV structural steel, the drying time should not exceed 2 hours. The number of re drying should not exceed 2 times.

【 Explanation 】 Low hydrogen welding rods are mainly used for important welding structures, and the requirements for low hydrogen welding rods are more stringent. Before packaging low hydrogen welding rods, they are generally subjected to strict baking at a temperature that meets the requirements for diffusion hydrogen, and packaged in sealed containers. If the sealed packaging is intact and used immediately after opening, baking is not necessary; However, if the packaging is damaged or used more than 4 hours after opening, it should be baked according to the provisions of this specification.

Low hydrogen welding rods are subjected to high-temperature baking before welding to remove crystal water and adsorbed water from the electrode coating. The main purpose is to prevent the moisture in the electrode coating from entering the weld metal through arc thermal decomposition during welding, which is one of the main factors causing delayed cracking in welding.

The welding problem inside the plugin machine is directly related to a major issue in the quality of subsequent output, just like some precision settings. Doing a good job of internal single and complex combination is for longer-term use and extension.

Chinese

Chinese

13829276376

13829276376